Conectamos la producción acuícola con la tecnología

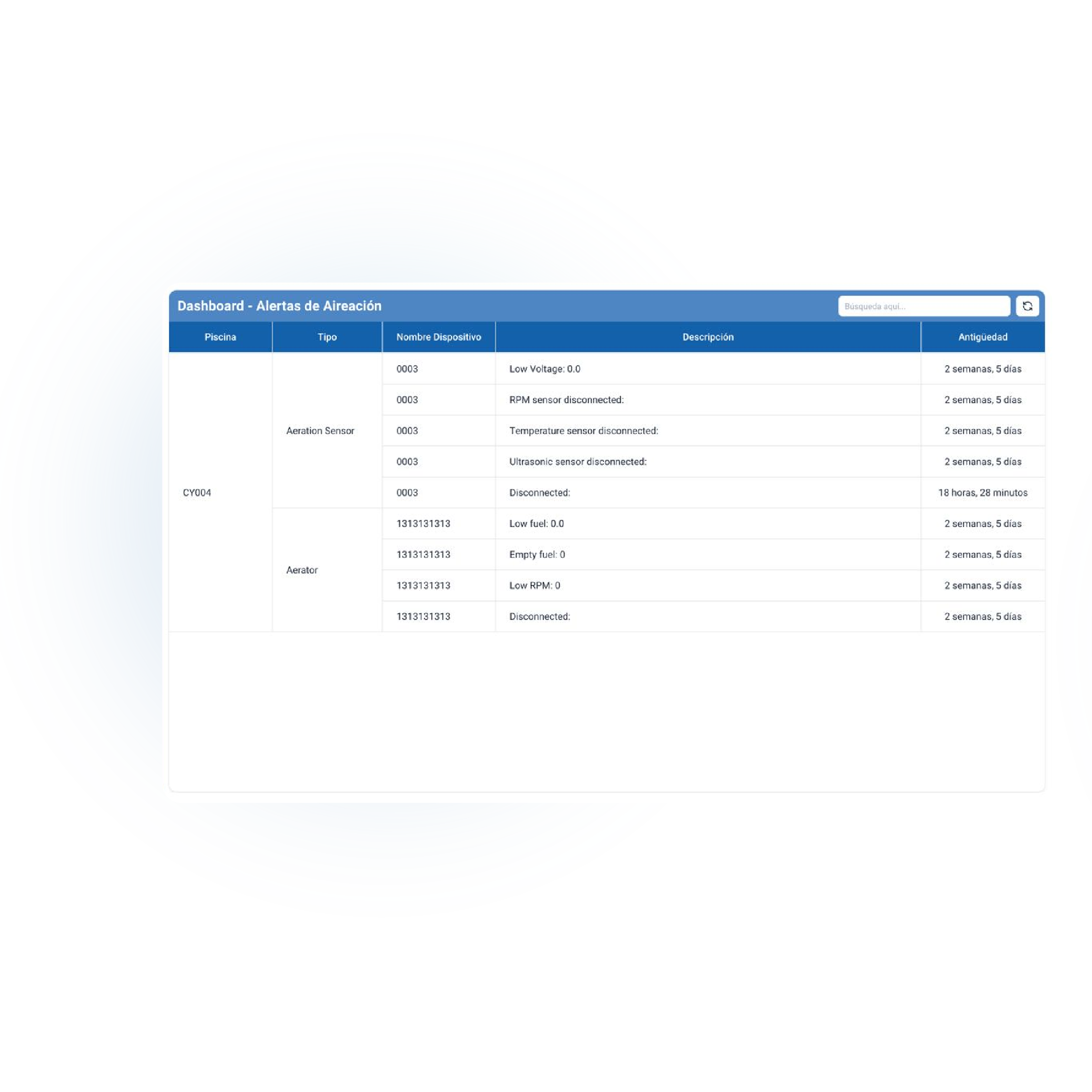

Smart Blue X impulsa la eficiencia, sostenibilidad y rentabilidad de la industria camaronera mediante soluciones tecnológicas automatizadas, fáciles de usar y 100% integradas.

Nuestro ecosistema digital permite monitorear, automatizar y optimizar cada proceso de producción desde un solo lugar.

- Tecnología diseñada para productores

- Soluciones confiables y autónomas

- Resultados medibles desde el primer ciclo